Cleaning industrial tanks

Fouling, or deposits and residue, will eventually build up on a tank’s inner walls and at its bottom as a result of the various materials and fluids stored inside it. Fouling on the interior walls of a tank will finally lead to a significant decrease in technological process efficiency. That is why a tank should be cleaned of all fouling and deposits each time it is emptied.

Periodic cleaning of tanks and vessels significantly improves the quality of the materials and fluids that are stored in them and prevents these materials from becoming tainted with the accumulated deposits. A tank clean-up is mandatory prior to an inspection by an expert from the Office of Technical Inspection (Polish: UDT).

In any sector of the industry, each day of downtime means lost revenue, that’s why we respond quickly to emergency situations and we can even send a crew on-site the next day.

Piotr StelmachAlpinJet President

making it impossible

implementation of the service

What is your tank cleaning technology based on?

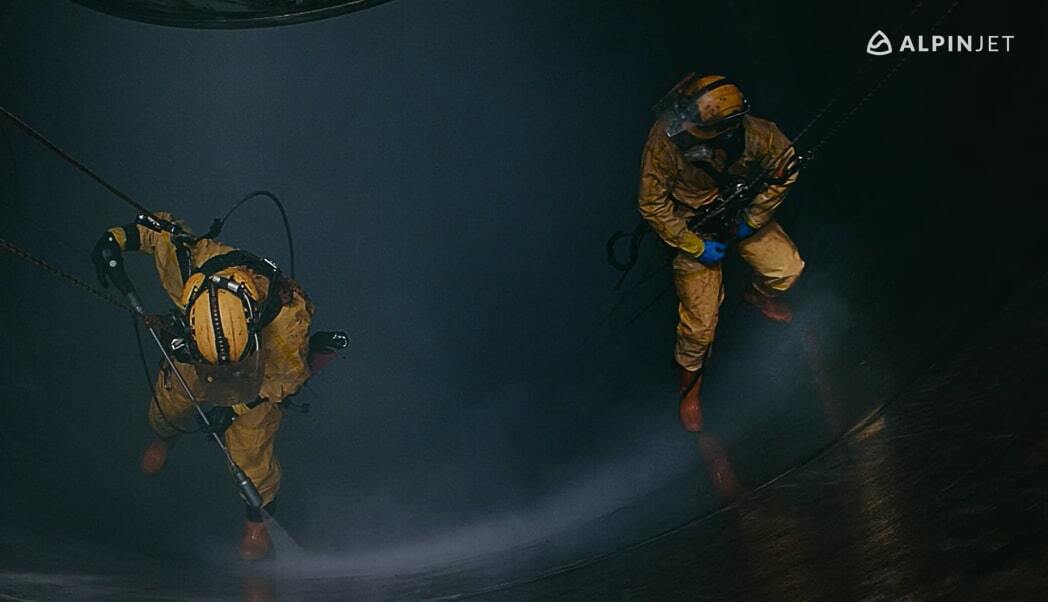

Our cleaning service is based on removing fouling and deposits from the tank’s interior walls and bottom by using high-pressure waterjets fitted with turbo nozzles. Larger tanks and vessels are accessed via scaffolding or rope access.

In no-drain tanks, jetted debris and water are removed using a mobile sludge pump. A dry storage tank can also be dried with a heater and dryer after it has been cleaned.

Why choose a high-pressure waterjet cleaning service?

Although industrial tanks and vessels can be cleaned via different methods, in many cases high-pressure waterjetting is still the best cleaning option.

Chemical cleaning of tanks is usually a high-cost option due to the large volume and size of the space that needs to be thoroughly cleaned. The results of mechanical cleaning are not always satisfactory, as this method is also much less efficient than cleaning using high-pressure waterjets.

Sandblasting is a cleaning option that might damage the surface of the tank’s inner walls. Sand is highly abrasive and scrapes the surface off, which can then lead to corrosion inside the tank. Also, the sand and sludge used to clean the tank have to be disposed of in a proper, environmentally sound manner.

It is important to note that in tanks in which dry or hazardous substances were stored, high-pressure waterjetting is the only cleaning option that minimizes residue dust combustibility. High-pressure waterjetting is also entirely environmentally friendly.

High safety procedures

We work in extremely dangerous and demanding environments. Operating at heights, inside a pipeline, in oxygen-deprived or flammable conditions or requiring the use of chemicals demands proper preparation and planning. We provide our cleaning services to full industry certification and strictly follow all safety procedures (Polish: BHP) during every cleaning project.

Each new employee joining our team goes through basic training and always starts as a high-pressure operator and/or industrial climber. Our industrial climbers are certified to conduct rope access work. Our most experienced waterjetting operators are qualified to operate tools at 2500 bar.

Our operators are equipped with their own sets of personal protective equipment to work in all types of hazardous environments, such as gas tight coveralls, full-face masks, and motion, low oxygen and chemical sensors. Only certified climbing equipment is used for cleaning tasks that require rope access work.

Besides conducting cleaning tasks in compliance with international policies and processes, we also implement our own, company-specific safety procedures that we have worked out over the years. Our procedures pertain to operator safety, proper choice of equipment and harnesses, and to the entire cleaning process.

Rope access

We can implement our rope access expertise and methods in any given cleaning project, which allows for greater overall flexibility and safety performance. Our work-at-height operators are certified by industry-leading associations such as IRATA and OTDL, and most of them are members of the Polish Alpinist Association.

Cleaning using rope access methods allows to efficiently remove fouling and debris where other cleaning methods and solutions would be more difficult or even impossible to implement. This is both time- and cost-effective for the client.

Although a cleaning task might not demand work-at-height operators, our team includes industrial climbers and cavers – professionals who are used to working in completely dark, confined and damp spaces – thus we can efficiently conduct cleaning operations in the most difficult, hard-to-access places.

Demanding work conditions

Most of our operators are cavers and divers, thus they are used to working in full-face masks in dark, damp and confined spaces. Even when the cleaning task doesn’t require rope access work, these skills allow them to work efficiently in extremely demanding conditions.

Why choose us?

Cleaning tanks is one of the most dangerous tasks we specialize in. We’ve completed hundreds of tank cleaning tasks, and we have the requisite expertise and know-how to successfully clean every type of tank.

All of our operators are well-trained, experienced professionals. Most of our operators are cavers and divers, thus they are used to working in the confined space and extreme conditions inside a tank.

Thanks to work-at-height and rope access certification (IRATA certified), our operators have access to restricted spaces where using traditional means such as scaffolding or a crane basket would be impossible.

We foster a highly rewarding, performance-based work environment. This translates into commitment and self-motivation from our experienced, full-time operators who make sure every task is completed in a highly efficient, timely manner.

Our company structure allows us to minimize the time frame we need to start a cleaning project in an emergency situation. We’ve been providing cleaning services throughout Poland for many years now.

Following safety standards and procedures is our top priority during tank cleaning operations. Our overall safety measures and proper choice of high-pressure equipment have allowed us to work accident-free since starting our cleaning business.

Experience

We have over 14 years’ experience in cleaning all types of industrial installations of various size, shape and use. Successfully completing cleaning projects across a variety of industrial sectors – from food & beverage to petrochemical – means we possess the hands-on experience and professional know-how necessary to handle any deep clean task to remove various types of fouling, sediment deposits and heavy debris.

The walls of a tank were cleaned in which resin hardener was stored and used for the production of a mineral binder.

An underground tank was emptied and cleaned. A suspended rope access tripod system was used for this demanding cleaning task.

We conducted a non-standard cleaning service involving glass bead blasting to remove carbon deposits from boiler tubes.

Industries we’ve worked for

production

production

processing

Equipment

We use mainly our own equipment during cleaning tasks. Our entire selection of tools and machines – from high-pressure water pumps through power units to pipeline cleaning nozzles – is purchased brand-new, directly from the manufacturers. This guarantees the highest quality of the tools we use and eliminates any unforeseen equipment failures. Our many years of experience allow us flexibility when selecting the optimal applications from each manufacturer’s array of ready-to-use equipment. If necessary, we can develop custom solutions and implement our own applications that are unavailable to competitive cleaning service providers. This allows us to adapt all our tools and equipment to meet the unique demands of each cleaning project.

pompy wysokociśnieniowe

dysz i głowic wysokociśnieniowych

głowic do czyszczenia dużych rurociągów

Highest standards guaranteed

There is no room for error in any industry – as time and reliability count the most – that is why we are dedicated to maintaining strong safety performance. We meet all safety standards as detailed in ISO 9001, 14001 and 45001 certification. For many years we belonged to the prestigious American WaterJet Technology Association (WJTA), and most of our rope access operators are Polish Alpinist Association members.

For many years, we belonged to the prestigious international WaterJet Technology Association (WJTA) which brings together key players in the waterjetting business.

We have ISO 9001, 14001 and 45001 certificates confirming compliance with safety standards for high-pressure waterblasting and rope access services.

Each project requiring the use of rope access methods is organized and supervised by a qualified Polish Alpinist Association instructor.

FAQs

Below are our answers to our clients’ most frequent questions regarding industrial tank cleaning.

What safety measures do you take when entering tanks?

Working and cleaning inside tanks is a particularly dangerous job, that is why we always have at least two operators to do the task. One operator works inside the tank and the assisting operator monitors the entire cleaning operation outside the tank. The operator entering the tank has a motion sensor that will send an alarm signal in an emergency situation, for example if the operator inside the tank becomes motionless or collapses. In hazardous zones, our operators also wear full-face masks fitted with ABEK filters, and in extreme and hazardous conditions they also wear a breathing apparatus (a full-face mask with exhalation valves and clean air supplied from a separate source). We always monitor oxygen levels and those of other potentially harmful gases before commencing work in poorly ventilated tanks. Cleaning tasks on large, vertical tanks are done via incorporating rope access methods. Wherever structurally prepared anchor points and devices are absent, we mount a portable tripod to allow for easy descent, ascent and to ensure any potential fall arrest.

Can high-pressure waterjetting damage the surface that is being cleaned?

That depends on how hard the built-up fouling, or scale, is and how strong the surface is on which that scale has accumulated. The least favorable situation is when hard scale has built up on a delicate surface, and in such cases, although extremely rare, it is practically impossible to remove all of the scale build-up.

Most industrial installations are made from carbon or acid-resistant steel, and such surfaces are resistant to the high-pressure water stream. Waterjetting is thus a non-abrasive and safe industrial cleaning method.

What types of fouling do you remove during the waterjetting operation?

We use high-pressure waterjetting equipment to clean various industrial fouling that has built up, including resins, glues, old paint coatings, paints, varnishes, tars, polymers, oils, waxes and greases, dusts and grit, rubber, petroleum substances, corroded concrete, limescale, rust, sludge and silts, algae, biofilm, most organic and inorganic substances and all other types of industrial-specific deposits.

Would you like to see our answers to other questions? Please go to our FAQs

Please contact our office if you have any questions or a cleaning project for us.

Our expert staff will contact you promptly to answer any questions.